The Most Trusted Metal Stamping Partner for the Filter Industry

A History of Excellence & High-Quality Standards

At the core of Newcan’s legacy is our deep specialization in manufacturing center tubes for the filtration industry – a product we’ve helped define for decades. But our expertise extends far beyond filtration. With more than 120 years of experience, we produce custom-engineered metal components for a wide range of markets.

By combining legacy knowledge with modern tooling and precision technology, we deliver high-volume, high-quality components built to exact specifications – ensuring performance, reliability and consistency across every application.

-

Meet and exceed the needs of customers through the continual improvement of our quality management system.

-

Remain committed to delivering high-quality, competitively priced products that arrive on time and rapidly respond to all customer requests.

-

Rely on our entire team to meet the objectives of our customers.

A Family Affair

Innovation is in our DNA. In fact, Newcan was involved in the development of spin-on oil filters in the late 1940s and was the first supplier of metal components used in the manufacturing of these filters.

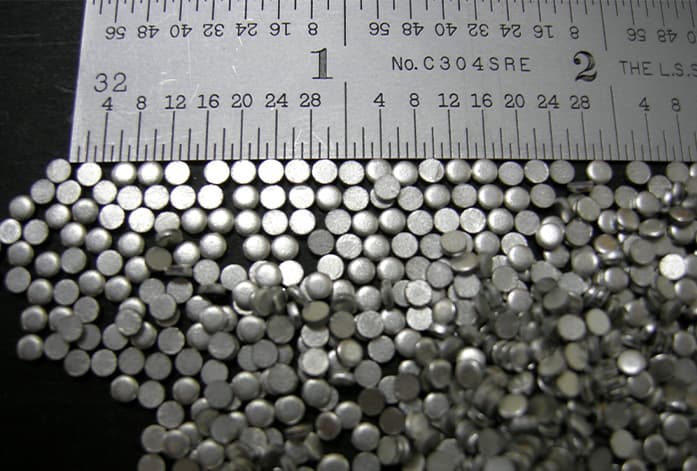

Since then, Newcan and our sister company, Falls Stamping & Welding, have worked in tandem to deliver precision-engineered, customer-designed components built to exact specifications. While Newcan specializes in light-gauge metal stamping and perforated solutions (ranging from .0095" to .033"), Falls Stamping expands our reach into heavy-gauge stamping, welding and complex assemblies, working with materials from .035" up to .500". Together, we offer a seamless, full-spectrum solution for customers with diverse part requirements – whether for filtration components, structural stampings or larger industrial assemblies.

Certified for Higher Standards

Newcan is certified to IATF 16949:2016, the most rigorous quality management standard in the automotive industry. While many competitors are certified to ISO 9001, IATF 16949 includes all ISO 9001 requirements plus additional controls for traceability, process consistency and risk management – especially critical for OEM and Tier 1 suppliers.

This certification reflects our commitment to zero-defect production, continuous improvement and complete accountability across every part we make. For our customers, it means greater confidence, fewer disruptions and a supplier you can rely on when quality and delivery matter most.

Newcan Through the Years

Read through our timeline to learn about our storied past – and how it continues to drive our future.

The Newcan Company was established by Mr. Julian Marzinski.

Newcan participates in development project for automotive "spin-on" oil filters.

Newcan transitions from producing decorative metal tins and cans for Campbell Soup to focusing on automotive spin-on oil filters, continuously developing its capabilities.

Control of The Newcan Company shifts from family members to American Acquisition Partners, a venture capital company located in Morristown, New Jersey. Management direction remained with Marsha Moeller, granddaughter of Mr. Marzinski, until 1999.

The Newcan Company earns ISO 9002 certification.

The Newcan Company achieves QS-9000 certification.

Ted Bustany takes over The Newcan Company as CEO.

The Newcan Company obtains registration to ISO 9001:2008 and ISO/TS 16949:2009 (now IATF 16949:2016).

The Newcan Company is acquired by the mutual owner of sister company, Falls Stamping & Welding.

Our Locations

Our centrally located facilities in Pulaski, Virginia, and Greenville, Ohio, as well as our sister company’s location in Cuyahoga Falls, Ohio, offer cost-effective solutions for your manufacturing needs.