Get Spiral Perforated and Louver Tubes

Precision-Engineered Spiral perforated and Louver Tubes for Maximum Flow & Flexibility

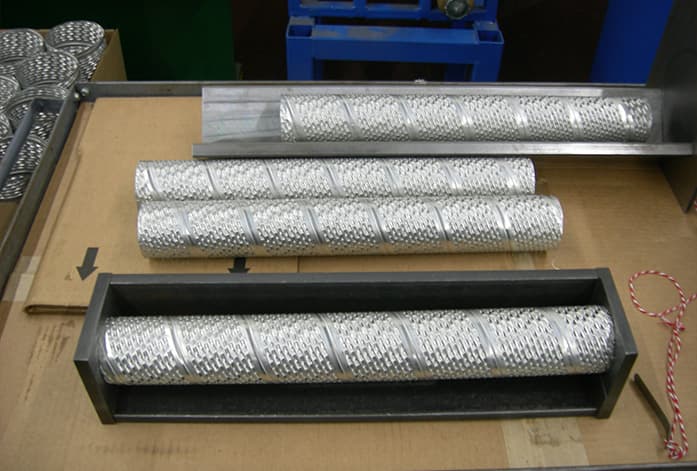

Newcan delivers the industry’s most complete line of spiral lockseam cores for the 1.085 string-wound filter market—engineered for durability, clean internal flow paths, and precise fit. Choose from stocked standard lengths in tin-plated steel, 304, and 316 stainless steel, or go custom with straight or spiral lockseam design with louver options. Whether you're a large OEM or a specialized filter manufacturer, we provide high-performance cores with fast turnaround and dependable quality you can count on.

Specializing in Perforated Tubes – But Offering More

At Newcan, perforated tubes are our specialty. Offering up to 65% open area, these tubes provide cleaner internal surfaces and superior flow efficiency compared to louvered alternatives. They’re ideal for filtration systems that require high throughput, minimal flow restriction and consistent performance.

While perforated tubes remain our specialty for their superior flow and cleanliness, we recognize that some applications demand louvered construction for specific airflow or structural requirements. That’s why Newcan offers both perforated and louvered tube options—ensuring you have the flexibility to choose the best fit for your system's performance and design needs.

Our Capabilities

- Diameter Range: 1" to 8"

- Material Thickness: .008" to .033"

- Tube Length: 2" to 120"

- Lockseam Types: Internal, External, Flush

- Perforation Options: Customizable patterns with open areas from 1.1% to 65%

- Benefits: Cleaner internal surfaces and superior flow efficiency compared to louvered designs

- Additional Options: Corrugated metal available upon request

- Diameter Range: 1" to 7.15"

- Material Thickness: .008" to .022"

- Tube Length: 2" to 120"

- Lockseam Types: External, Flush

- Louver Designs: Single or double-louvered configurations for tailored flow control

- Strength Advantage: Enhanced strength-to-weight ratio through formed louvers

- Use Case: Ideal when specific airflow resistance or strength profiles are required

- Outside Diameter: 1.085" and Wildcat 1.744"; additional diameters may be considered

- Standard Lengths: 9.875", 19.875", 29.875", and so on (custom lengths available on request)

- Material Options: Tin-plated steel, 304 stainless steel, 316 stainless steel

- Built For: String-wound filtration applications (no synthetic cores offered)

- Stock Program: Common sizes stocked for quick-turn availability in one carton shipping increments

- Ideal For: Small and mid-sized filter manufacturers needing high-quality, cost-effective cores

Value-Added Services to Enhance Performance and Finish

Newcan doesn’t stop at precision forming—we ensure your spiral tubes and 1.085 cores are production-ready with a full range of post-manufacturing services. From washing and tin plating to e-coating, passivation, anodizing, and Mil-Spec treatments, we prepare every part to meet your final application’s durability, appearance, and compliance requirements. These finishing options are available across our full line of perforated and louvered tubes, so you receive components that perform right out of the box.

Why Choose Newcan for Your Perforated & Spiral Tube Components?

Exceptional speed, service and precision – every order, every time.

Quick Turnarounds You Can Count On

With stocked standard sizes and efficient production capabilities, we deliver even niche or custom tube orders fast – supporting tight schedules and minimizing downtime.

Customer Service That’s Personal & Proactive

From quoting to delivery, our team works closely with you to understand your specs, solve challenges and ensure you get exactly what you need – with no surprises.

Precision You Can Rely On

Every tube is built to exacting standards using advanced tooling and process controls – so you can trust the fit, flow and performance of each component we produce.